Photonics Assembly & Testing

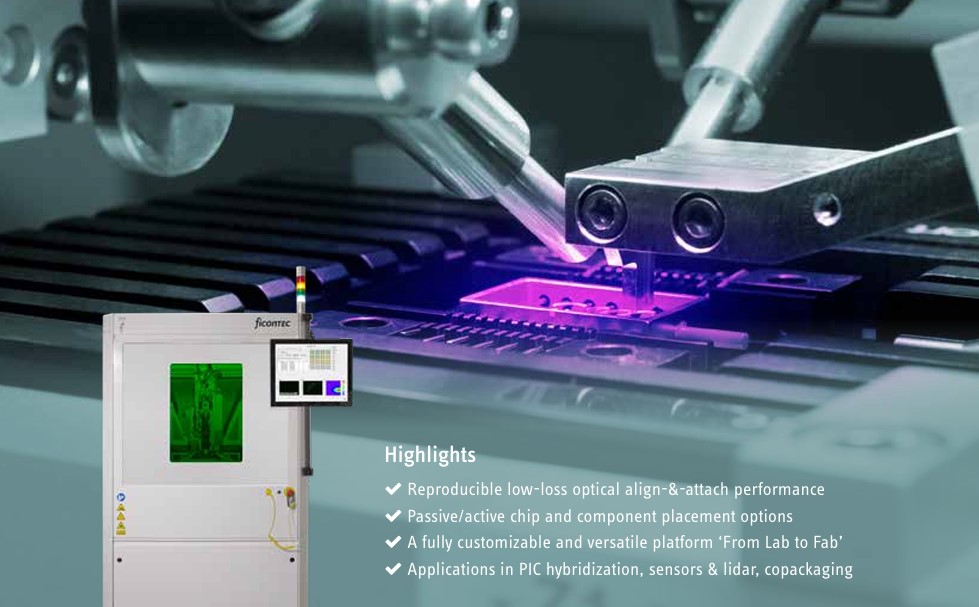

Automated Die-Level Photonic Device Assembly

Fully automated, industry-qualified assembly for optoelectronics and singulated photonic devices and PICs. Featuring high-precision ‘align-&-attach’ bonding capability for all optical elements, fibers and arrays, as well as for die, chip or PIC integration and hybridization.

Flexible, multi-purpose ‘align-&-attach’ platform

A highly capable development and/or batch processing platform, uniquely combining high-precision optical alignment capability with a multiplicity of bonding technologies. Designed for all optical, fiber and die/chip/PIC connection and hybridization tasks.

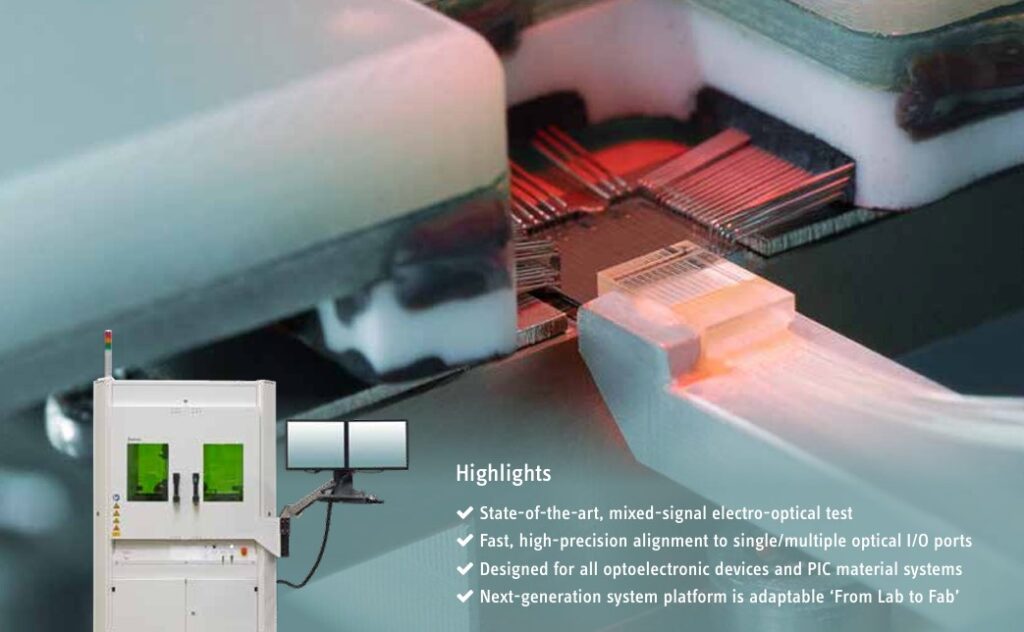

Fully automated die-level photonic device test

Fully automated, mixed-signal electro-optical test systems for optoelectronics and singulated photonic devices. Featuring DC, RF and optical measurements in a production-optimized modular layout, and targeted at R&D, volume manufacturing, and anything in between.

Fully automated electro-optical wafer-level device test

Innovative mixed-signal electro-optical test systems for non-singulated photonic integrated circuits (PICs) and other optoelectronic devices. Featuring fully automated DC, RF and optical measurements both on-wafer and for single photonic devices on appropriate carrier formats.

Laser Bar Stacking

Fully automated precision stacking/unstacking for semiconductor laser diode bars. Typically used in preparation for a coating process, and/or for post-process unstacking and optical inspection of facet and side walls (optional). Configurable as a stand-alone or as an in-line assembly cell.

Quick Links

+ Home

+ Projects

+ Resources

+ Achivements

+ Make in India

Products

+ Motion Control

+ Spectroscopy

+ Imaging

+ Radiometry & Photometry

+ Vibration Control

Quick Links

+ Home

+ Projects

+ Resources

+ Achivements

+ Make in India

Connect with Us

Corporate Office :

619, Nirmal Lifestyles Corporate Center, LBS Marg Mulund West, Mumbai 400080

Email :

sales@advancedphotonicsindia.com

Phone:+91-22-3504 8294